spakey

Club Member

Heavy rain while on tour and the left indicator and high beam warning lights on the centre console dash stopped working, after a dry spell they worked again (Fatboy 2016). Now I've had a chance to look at it all the connectors in the console and they are dry and clean so put it back together and they stopped working again  . Searching the 'tinternet it seems a common problem with the only solution to buy a new harness assembly at £160

. Searching the 'tinternet it seems a common problem with the only solution to buy a new harness assembly at £160  (the dash light circuit board is hard wired to speedo/switch/pump harness p/n 72657-12)

(the dash light circuit board is hard wired to speedo/switch/pump harness p/n 72657-12)

Diagnostic mode to light all the console lights, no left indicator or high beam lights.

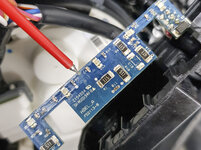

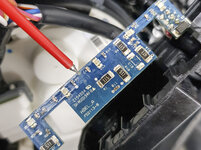

So I took the console apart again and managed to get the circuit board out this time. Console circuit board is inside a plastic box (centre of this pic)

I checked all the harness solder connections on the right of the board, all good. Then I switched the ignition on and tried to test the LED's for power, all good on the right (right indicator, oil and neutral) but the two on the left had no power. Then I noticed a tiny corrosion spot on the board between the R9 and the C4 components (I think that's a resistor and a capacitor)

I rubbed a fingernail over it, the two left LED's lit up for moment and then went out. The corrosion was a small redundant solder pad in the connection track that runs along the top of the board (from DS1 on the left to R12 about centre), you can just make it out in the first pic of the board. With that small solder pad corroded away there was now a break in the power connection so I've now soldered a jump wire across the break.

I soldered across the LED pads as they are a little bigger and easier to get the solder on, you can use R9 and C4 if you're very good with a soldering iron but it makes no difference. Looks like it's all working now so I'll put a good smear of electralite grease over everything, get it back together and see if it lasts

I did need to notch the plastic cover out a little to clear the new wire jump.

Notched cover

Hopefully it will last.

I did find an alternative fix on my search that might work. The earlier models (2011) have a different harness with a connector for this LED circuit board, p/n 69029-11 which you could use the board from to replace the old one on the existing harness or maybe cut off new connector and just splice it in. I found this part in the UK for £65, not cheap but better than £160.

Diagnostic mode to light all the console lights, no left indicator or high beam lights.

So I took the console apart again and managed to get the circuit board out this time. Console circuit board is inside a plastic box (centre of this pic)

I checked all the harness solder connections on the right of the board, all good. Then I switched the ignition on and tried to test the LED's for power, all good on the right (right indicator, oil and neutral) but the two on the left had no power. Then I noticed a tiny corrosion spot on the board between the R9 and the C4 components (I think that's a resistor and a capacitor)

I rubbed a fingernail over it, the two left LED's lit up for moment and then went out. The corrosion was a small redundant solder pad in the connection track that runs along the top of the board (from DS1 on the left to R12 about centre), you can just make it out in the first pic of the board. With that small solder pad corroded away there was now a break in the power connection so I've now soldered a jump wire across the break.

I soldered across the LED pads as they are a little bigger and easier to get the solder on, you can use R9 and C4 if you're very good with a soldering iron but it makes no difference. Looks like it's all working now so I'll put a good smear of electralite grease over everything, get it back together and see if it lasts

I did need to notch the plastic cover out a little to clear the new wire jump.

Notched cover

Hopefully it will last.

I did find an alternative fix on my search that might work. The earlier models (2011) have a different harness with a connector for this LED circuit board, p/n 69029-11 which you could use the board from to replace the old one on the existing harness or maybe cut off new connector and just splice it in. I found this part in the UK for £65, not cheap but better than £160.